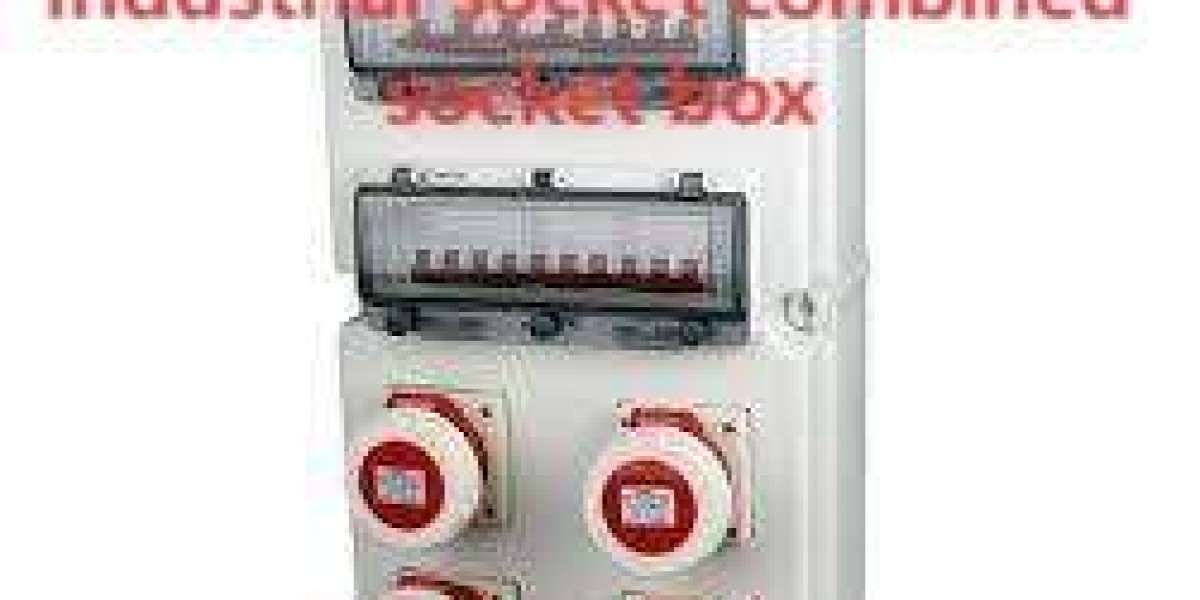

Reliable temporary and permanent power setups depend on the right enclosure, and choosing the correct industrial socket combined socket box is often the difference between safe operation and costly downtime. In many sites, a single, well-specified industrial socket combined socket box can centralize multiple outlet types, protect connections from the elements, and simplify wiring layouts, making it easier for electricians and site managers to deploy power quickly and securely.

Why Integrated Enclosures Improve Site Efficiency

Combining several socket types and control elements into one enclosure reduces installation time and minimizes cable runs. Instead of multiple loose outlets scattered across a work area, an integrated unit provides a tidy, labeled point of access. This reduces tripping hazards, makes inspection simpler, and speeds fault-finding when a circuit trips. Projects that value fast turnaround and clean installation benefit immediately from this consolidation.

Key Design Considerations for Tough Environments

When selecting an enclosure, materials and ingress protection are vital. Look for impact-resistant housings, secure gland plates for cable entry, and reliable sealing to prevent water or dust intrusion. Internal layout is equally important: ample space for terminations, clear separation of load circuits, and provision for future expansion avoid cramped wiring that can generate heat and complicate maintenance.

Safety Features That Matter On Site

Good enclosures include user-friendly safety features such as lockable covers, clear earth bonding points, and easily accessible isolation switches. Labeling of individual outlets and protective devices reduces operator error during connection and disconnection. Thermal management—through ventilation or heat-tolerant components—helps ensure the equipment runs within safe temperature limits under heavy load.

Nante’s Site-Ready Configurations

Nante offers models aimed at common field requirements: versions with multiple industrial outlets, fused protection, and optional RCDs for additional safety. These preconfigured units reduce lead times and simplify specification for contractors. Models intended for harsh locations include reinforced fixings and UV-stable finishes, making them suitable for outdoor events, construction projects, and temporary power supplies.

Installation and Maintenance Best Practices

Mount units at a height that balances accessibility and protection from accidental impact. Use flexible conduits or armored cable where movement or abrasion is likely, and ensure glands are tightened to maintain the enclosure’s seal. During handover, provide a simple circuit map and label each outlet. Regular inspections should check gaskets, fixings, and the integrity of cable entries—small preventive checks avoid larger failures later.

Choosing the Right Capacity and Modularity

Think ahead about likely load growth. A box with spare space or modular mounting rails allows future upgrades without a full replacement. Modular designs that accept plug-in protective devices make swapping fuses or breakers quicker on site. When procurement allows, specifying slightly larger enclosures up front can save both time and money as requirements evolve.

Practical Use Cases Across Sectors

These combined enclosures are common in construction for powering tools and site offices, in events for stage and vendor power, and in industrial settings for temporary maintenance feeds. Landscapers and agricultural operations also benefit from weather-resistant options for irrigation pumps and outdoor lighting. The single-point approach simplifies logistics when multiple teams share a power source.

Documenting And Training For Safer Operation

Provide straightforward user guidance with each installation: show how to isolate the box, reset protective devices, and safely connect equipment. Training reduces reliance on emergency callouts and helps site staff handle minor issues themselves. Keep records of maintenance and any component replacements to support warranty claims and future audits.

Long-Term Value And Lifecycle Thinking

High-quality enclosures save money over their lifetime. Robust materials, sensible internal design, and easy maintainability reduce replacement frequency and downtime. When combined with good maintenance practices, a well-chosen unit minimizes total cost of ownership and supports reliable operations for years.

For teams specifying or purchasing combined power enclosures, focusing on safety, flexibility, and serviceability will deliver the best outcomes. Explore product options and technical details at www.nante.com/product/