Across the modern industrial landscape, Naishi, an established Trunnion Mounted Ball Valve Factory, continues to redefine engineering reliability through corrosion resistance, structural endurance, and custom global application. Its fully welded trunnion mounted ball valves are built to function in harsh climates, corrosive media, and long-distance energy transport systems where stability and lifespan dictate operational safety. The combination of design refinement and metallurgical precision allows each valve to maintain consistent sealing performance despite environmental stress or time-induced wear.

The science behind corrosion resistance begins with the deliberate choice of raw materials and protective coatings. Alloys with high chromium and nickel content form the base of the valve body, providing an intrinsic barrier against chemical attack. Surface treatment techniques such as electropolishing and nitriding further enhance molecular density, reducing porosity and preventing corrosion pitting. The result is a valve capable of maintaining flow integrity in saline, acidic, or high-humidity environments, where traditional metals would otherwise degrade or lose efficiency.

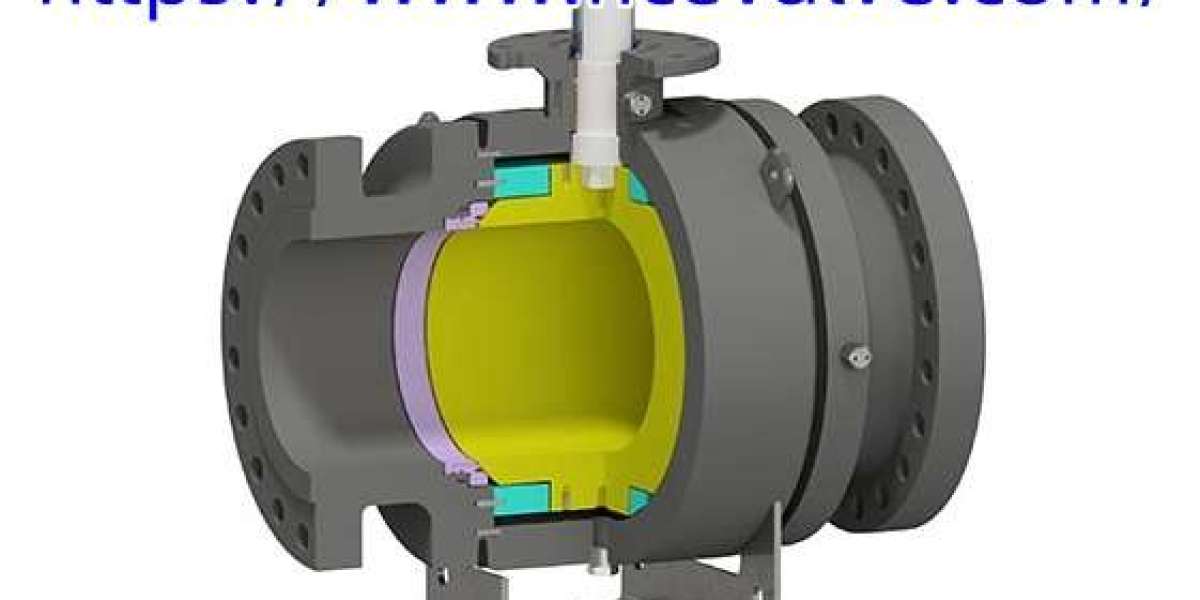

Structural durability is achieved through a combination of geometry, weight distribution, and weld design. The trunnion-mounted construction ensures that internal pressure loads are absorbed evenly across the valve body, preventing distortion and maintaining seal contact integrity. Weld joints are inspected with precision imaging to verify full penetration and microstructural uniformity, ensuring that mechanical stress does not compromise performance. By reinforcing structural continuity through both design and testing, the valve becomes a unit that performs not just under pressure, but through years of cyclical operation.

Customization is an equally vital part of the factory's identity. Industrial systems vary greatly in scale and purpose—from offshore pipelines to underground distribution grids—each demanding unique technical parameters. The engineering team collaborates with clients to adjust bore dimensions, pressure ratings, and coating materials according to specific operational requirements. Every tailored configuration follows the same core standards of reliability while addressing localized challenges such as chemical exposure or mechanical vibration. This adaptability transforms each order from a standard product into a purpose-built solution aligned with regional and industrial expectations.

The global footprint of these valves extends across energy networks, processing facilities, and infrastructure systems where reliability is synonymous with safety. International certifications validate the factory's adherence to recognized standards, while ongoing partnerships with engineering contractors ensure that product design evolves with the changing dynamics of industrial technology. Through this commitment, the manufacturing philosophy transcends the idea of production—it becomes a continuous pursuit of global consistency supported by engineering accuracy and environmental responsibility.

As a professional Trunnion Mounted Ball Valve Factory, Naishi upholds its mission of precision and endurance through innovation and cooperation. Its fully welded trunnion mounted valve series represents not only a component of flow control but a testament to mechanical trust. Discover the details at https://www.ncevalve.com/product/fully-welded-ball-valve-1/fully-welded-trunnion-mounted-valve.html