Introduction to Gear Rack Versatility

Precision Gear Racks are essential components in mechanical systems that convert rotational motion into linear motion with high accuracy and reliability. Their applicability spans a wide range of industries, including CNC machining, robotics, automated assembly lines, material handling systems, and precision instrumentation. The suitability of a gear rack for a specific application depends on factors such as load capacity, precision requirements, speed, environmental conditions, and integration with other components.

CNC Machines and High-Precision Applications

In CNC machines, milling centers, and cutting equipment, high positional accuracy is critical. Precision Gear Racks in these systems provide linear motion for tool heads or worktables, ensuring repeatable and precise movement. Gear racks with high stiffness, minimal backlash, and smooth tooth engagement are preferred to maintain machining tolerances. Additionally, heat-treated and hardened racks reduce wear over time, ensuring consistent performance in demanding industrial environments. The choice of rack profile and material is directly influenced by the precision requirements of the specific CNC application.

Robotics and Automated Systems

Robotic arms and automated assembly systems benefit from the linear motion offered by gear racks. In these applications, load distribution, dynamic response, and vibration damping are crucial. Precision Gear Racks with appropriate rigidity and bending resistance ensure stable motion under variable loads, reducing errors and enhancing cycle efficiency. Custom rack lengths and mounting options allow integration into robotic systems with constrained space while providing reliable performance under continuous operation.

Material Handling and Heavy Load Applications

For material handling systems, such as automated conveyor systems, lifting platforms, or industrial carts, load capacity and durability are more critical than micrometer-level accuracy. Gear racks in these scenarios are often designed with thicker cross-sections, reinforced mounting points, and wear-resistant materials to handle heavy loads while maintaining smooth motion. Although precision is still important to ensure alignment, robustness, and longevity often take precedence over extremely tight tolerances.

Specialized Machinery and Environmental Considerations

Certain machinery, including packaging equipment, medical devices, and laboratory instruments, requires specialized gear racks that combine precision with environmental resilience. For example, stainless steel or coated racks may be necessary for corrosive or high-humidity environments, while lightweight aluminum racks may be used in portable or low-load applications. The adaptability of gear rack design—through material selection, tooth profile, and length customization—enhances its applicability across diverse operational conditions.

Design and Integration Factors

When selecting a Precision Gear Rack for any system, engineers must consider compatibility with the pinion, mounting options, linear guides, and system dynamics. Proper alignment, support, and lubrication are essential to maximize performance and extend service life. Additionally, understanding the specific load cycles, speed requirements, and environmental stresses allows for informed material and design choices that optimize system efficiency and reliability.

Conclusion on Cross-System Applicability

In conclusion, Precision Gear Racks are versatile components suitable for a wide variety of mechanical systems, from high-precision CNC machines to heavy-duty material handling equipment. Their performance depends on factors such as load capacity, rigidity, material selection, and integration design. By carefully evaluating the operational requirements of each system and selecting the appropriate rack specifications, engineers can ensure reliable motion, longevity, and efficiency. This versatility makes Precision Gear Racks a critical element in modern industrial automation and mechanical design.

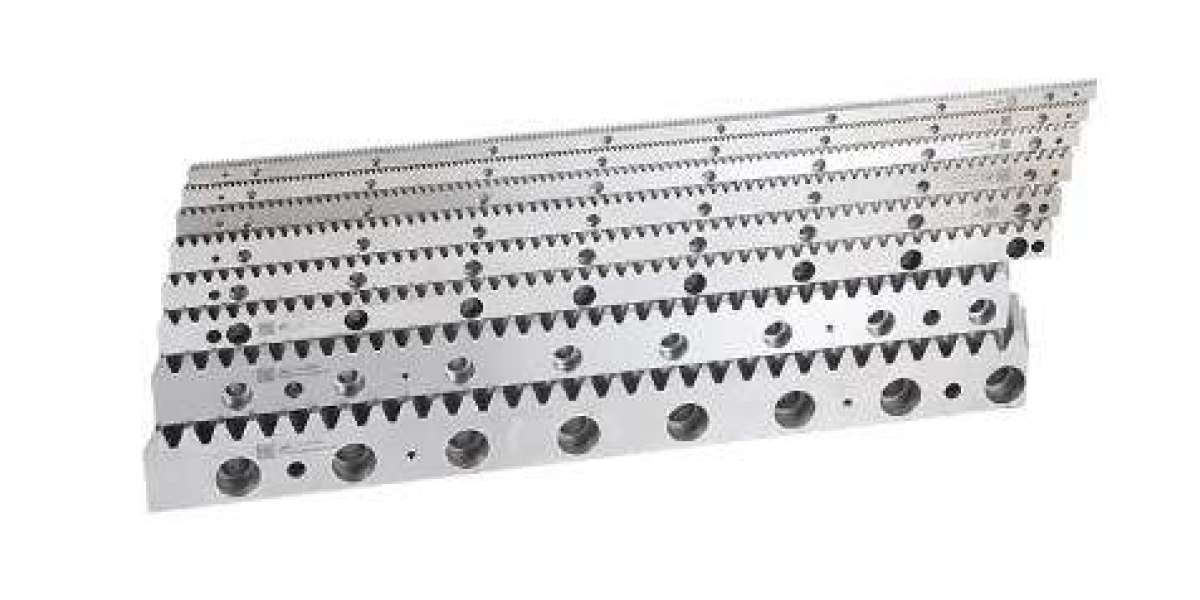

Technical requirement

Quality Grade: DIN 6

Material: S45C/42CrMo

Tooth profile: helical teeth

Right Hand Angle: 19°31'42"

Hardness treatment: high frequency quenching HRC48-52/ HRC50-55°

Production process: Ground on all sides after hardening