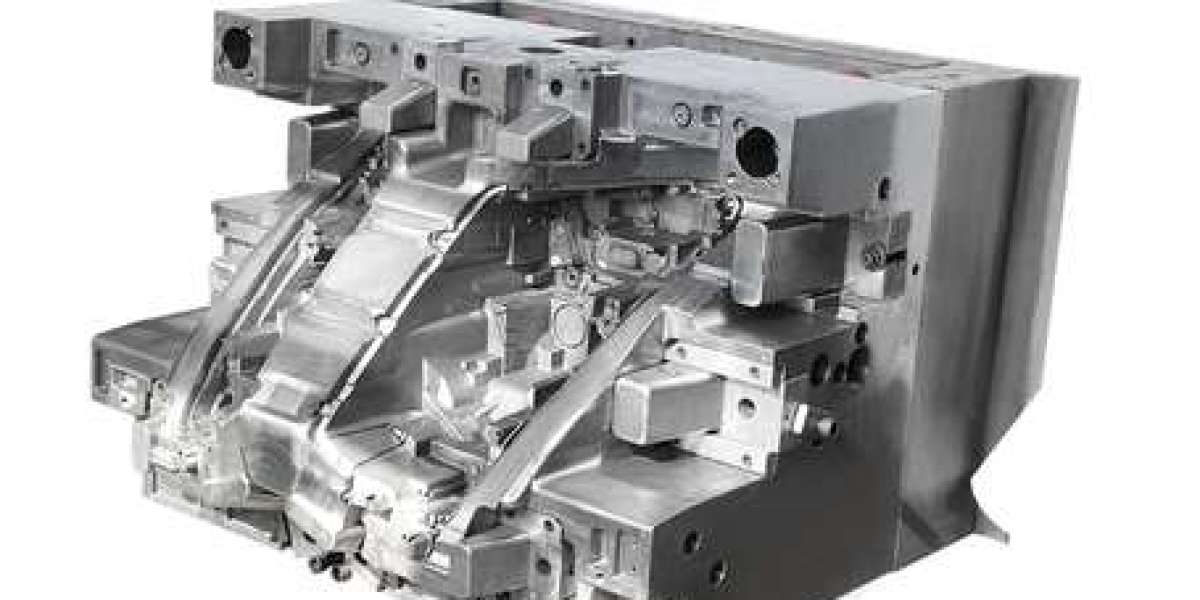

Automotive Plastic Injection Moulding supports the large-scale production of vehicle components that require repeatable accuracy and mechanical stability. This process transforms engineered plastic materials into functional shapes that integrate seamlessly into vehicle systems. Its efficiency and adaptability have made it a standard approach for many automotive applications.

Part design strongly influences moulding success. Automotive Plastic Injection Moulding requires careful evaluation of wall thickness, rib placement, and reinforcement features. These elements affect material flow and cooling behavior. Balanced design reduces the risk of warping and supports consistent surface appearance across production batches.

Thermal management remains a defining factor. During Automotive Plastic Injection Moulding, molten plastic enters the mould at controlled temperatures. Cooling speed influences shrinkage and internal stress. Engineers design cooling channels to distribute temperature evenly, allowing parts to solidify uniformly. This practice helps maintain dimensional reliability over time.

Structural components produced using Automotive Plastic Injection Moulding often replace heavier alternatives. Plastic brackets, housings, and supports contribute to vehicle weight reduction without sacrificing functional performance. This shift supports broader efficiency targets across automotive development.

Surface quality also receives close attention. Many automotive parts remain visible to end users, requiring smooth finishes or defined textures. Automotive Plastic Injection Moulding allows surface characteristics to form directly during production. Texturing or patterning inside the mould cavity eliminates the need for post-processing steps.

Assembly efficiency benefits from moulded-in features. Clips, guides, and fastening points integrated during Automotive Plastic Injection Moulding reduce reliance on additional hardware. This integration shortens assembly time and lowers part complexity. Fewer components also simplify inventory management.

Durability testing forms an essential part of validation. Automotive Plastic Injection Moulding components undergo mechanical and environmental evaluation to confirm long-term performance. Exposure to heat, vibration, and repeated loading simulates real operating conditions. Feedback from these tests guides refinement before full production approval.

Process stability supports predictable scheduling. Automotive Plastic Injection Moulding operations rely on repeatable cycle times and controlled parameters. Monitoring systems track pressure and temperature during each cycle, allowing rapid identification of variation. Stable processes reduce scrap rates and support efficient resource use.

Innovation continues to influence this manufacturing field. New plastic formulations and simulation tools enhance Automotive Plastic Injection Moulding capabilities. Digital analysis supports mould design decisions before physical production begins, reducing trial cycles and development time.

Automotive Plastic Injection Moulding remains a vital element within vehicle manufacturing strategies. Its ability to deliver consistent, functional components across large volumes ensures continued relevance as automotive systems grow more complex and integrated.