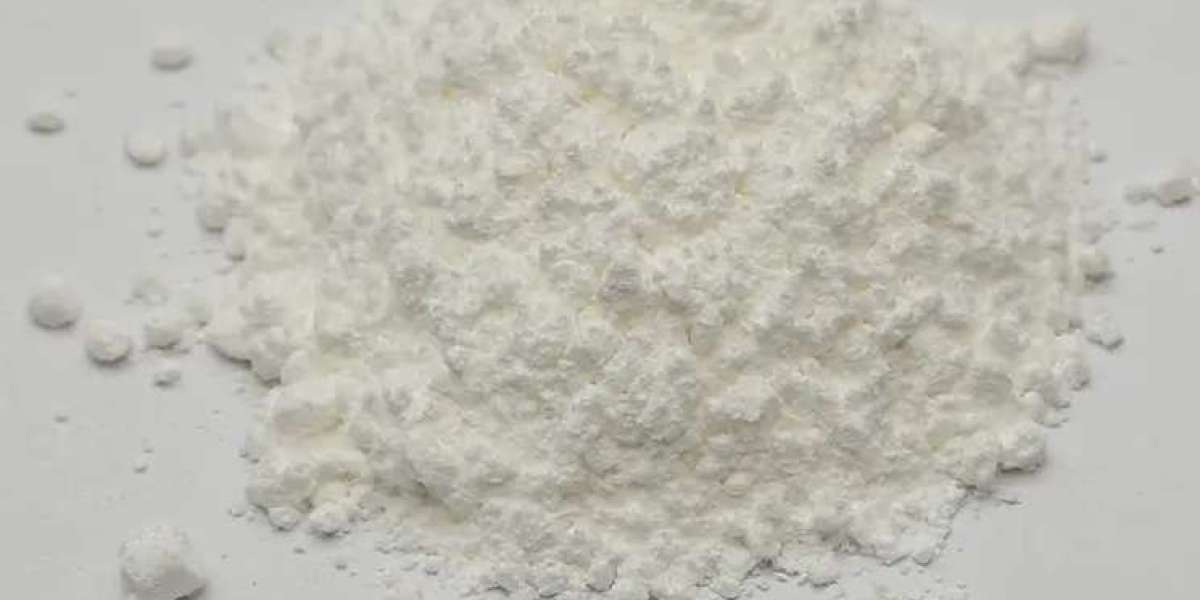

Introduction to Melamine Resin

Melamine Resin is a thermosetting polymer widely used in coatings, laminates, adhesives, and molded products. Its popularity stems from unique properties such as high hardness, chemical resistance, and excellent thermal stability. However, like any material, it has both advantages and disadvantages when compared to other types of resins, including epoxy, phenolic, and urea-formaldehyde resins. Understanding these differences is essential for selecting the right resin for specific industrial and commercial applications.

Advantages of Melamine Resin

One of the main advantages of melamine resin is its exceptional hardness and scratch resistance. This makes it ideal for decorative laminates, kitchen countertops, and furniture surfaces that require durability. Additionally, melamine resin offers excellent heat resistance, allowing products to maintain structural integrity even under elevated temperatures. Chemical resistance is another significant benefit, as the resin can withstand exposure to acids, bases, and detergents without degradation, making it suitable for industrial coatings and kitchenware.

Melamine resin also provides excellent dimensional stability, meaning it retains its shape and size under various environmental conditions. This property is particularly important in molded products and laminates. Moreover, its ability to form transparent or opaque coatings allows for versatile aesthetic finishes, which is a key advantage in consumer products and decorative applications.

Disadvantages Compared to Other Resins

Despite these benefits, melamine resin has some limitations. Compared to epoxy resins, it has lower flexibility and impact resistance, making it more prone to cracking under mechanical stress. While it is chemically resistant, it is generally more brittle than phenolic resins, which can limit its use in structural applications requiring high toughness. Additionally, the curing process of melamine resin often requires higher temperatures, which can increase production costs compared to other resins like urea-formaldehyde.

Another consideration is environmental and health concerns. Melamine resin is a formaldehyde-based resin, and although emissions can be controlled, improper handling or curing can release formaldehyde, which is hazardous. This makes regulatory compliance and proper processing crucial when using melamine resins in consumer products.

Application Considerations

Choosing melamine resin over other resins depends on the specific requirements of the application. For decorative laminates, kitchenware, and coatings, its hardness, chemical resistance, and heat stability outweigh its brittleness. However, for applications requiring flexibility, high impact resistance, or lower curing temperatures, other resins like epoxy or polyurethane may be more suitable. Evaluating the balance between mechanical properties, processing conditions, and cost is essential for optimal material selection.

Melamine Resin offers notable advantages, including hardness, heat resistance, chemical resistance, and aesthetic versatility. However, it also has disadvantages such as brittleness, higher curing temperatures, and potential formaldehyde emissions. Understanding these pros and cons in comparison to other resins allows manufacturers and designers to make informed decisions, ensuring the selected resin meets both performance and safety requirements in the intended application.