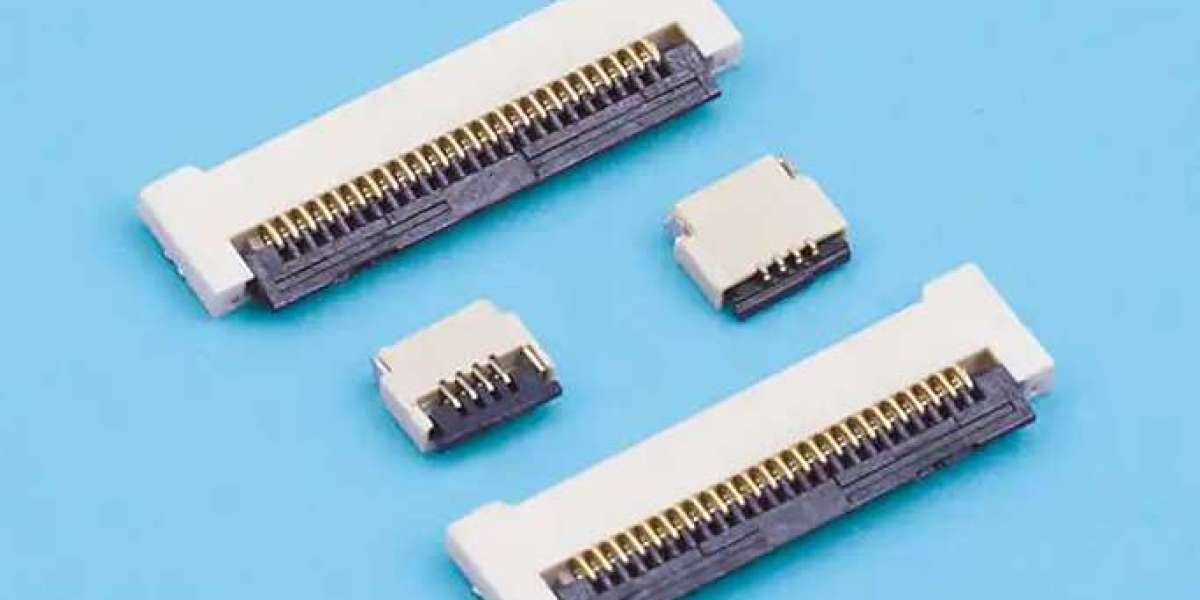

Why Connector Height Matters

Selecting the appropriate connector height is a crucial decision in modern electronic product design, especially as devices continue to become thinner and more integrated. The height of an FPC Connector directly influences how flexible printed circuits interface with rigid PCBs, affecting mechanical fit, electrical reliability, and overall product thickness. An unsuitable height choice can lead to assembly difficulties, excessive mechanical stress, or wasted internal space, all of which may compromise product performance and durability.

Understanding Mechanical Stack-Up Requirements

One of the first considerations in height selection is the total mechanical stack-up of the product. This includes PCB thickness, FPC thickness, stiffeners, shielding layers, and the enclosure design. In ultra-thin consumer electronics, designers often prioritize low-profile connectors to meet strict thickness targets. However, extremely low heights reduce tolerance margins and can increase the risk of misalignment during assembly. Choosing the right height, therefore, involves balancing slim form factors with sufficient mechanical clearance for reliable mating.

Assembly Process and Manufacturing Tolerances

The intended assembly method plays a significant role in determining optimal connector height. Automated assembly processes generally benefit from connectors that offer slightly more vertical tolerance, improving insertion accuracy and reducing damage to delicate FPC tails. Taller connectors can also simplify inspection and rework if required. On the other hand, manual assembly or space-constrained layouts may favor lower profiles. When selecting an FPC Connector, designers must ensure that the chosen height aligns with realistic manufacturing capabilities and acceptable tolerance ranges.

Reliability Under Stress and Environmental Conditions

Connector height also affects how mechanical stress is distributed across solder joints and contact areas. Very low-profile designs may concentrate stress at the solder interface, particularly during thermal expansion or vibration. Slightly increased heights can help absorb mechanical movement and improve long-term reliability in applications exposed to temperature changes or repeated motion. This consideration is especially important in automotive, industrial, or portable electronics, where durability is a key requirement.

Electrical Performance Considerations

Although height is often viewed as a mechanical parameter, it can influence electrical behavior as well. The vertical distance between contacts and reference planes can affect impedance control and signal integrity, particularly in high-speed or low-voltage applications. A well-chosen height helps maintain consistent contact geometry and stable electrical characteristics, reducing the risk of signal degradation caused by uneven mating or micro-movements.

Matching Height to Application Needs

Different applications prioritize different aspects of connector performance. Consumer electronics typically emphasize minimal height and compact aesthetics, while industrial equipment may accept slightly taller connectors in exchange for easier handling and higher robustness. Future scalability is another factor, as selecting a height with some design margin can accommodate minor layout changes or upgraded FPC designs without requiring a complete redesign. By carefully evaluating mechanical constraints, assembly processes, reliability expectations, and electrical requirements, engineers can confidently select the most suitable connector height for their specific application.

1、 CKT: 13Pin to 71Pin

2、 Current rating: 0.2A AC/DC

3、Voltage rating(max): 30V, AC/DC

4、Working Temperature: -25°C~+85°C, (Including temperature rise in applying electrical current)

5、Contact resistance:Initial value ≤40mΩ After environmental testing ≤60mΩ

6、Insulation resistance:≥50MQ

7、Withstand voltage:500VAC(rms)

8、Applicable PCB board thickness:1.6mm to 2.0mm