Cable management often becomes a practical concern long before a project is finished. In construction zones, warehouses, exhibitions, and temporary work areas, exposed cables can be damaged by vehicles, carts, or frequent foot traffic. This is where a Cable Protector plays a visible and functional role. Rather than being an accessory, it is a working component that supports orderly operations and protects valuable wiring assets.

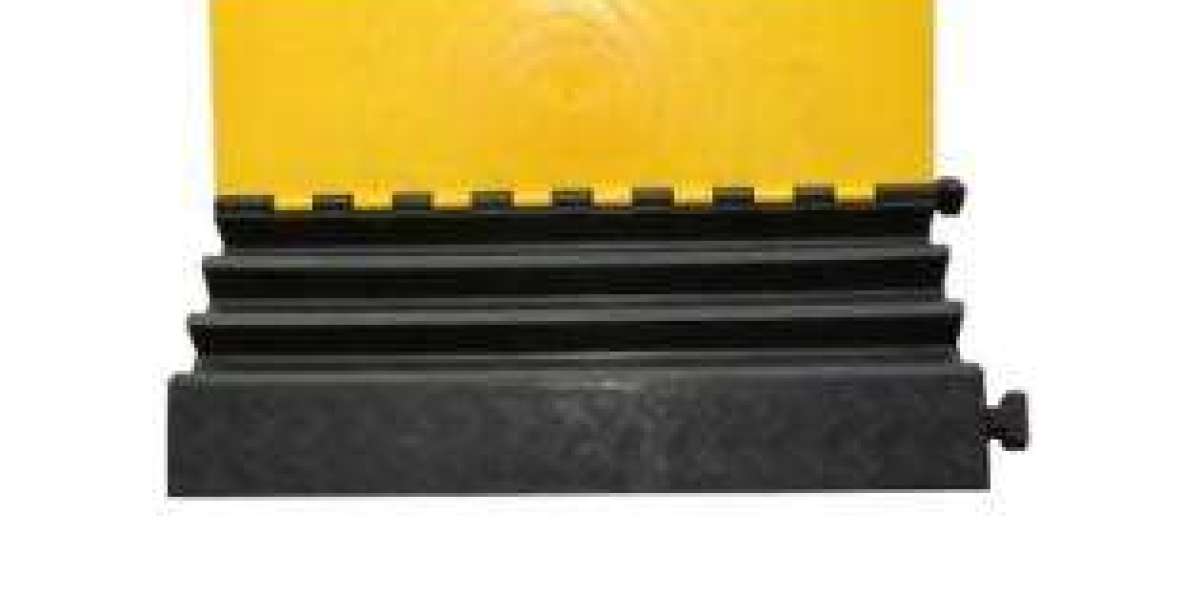

A well-designed Cable Protector helps guide cables into fixed channels, reducing random movement and surface wear. For B2B buyers, the interest usually goes beyond appearance. Load-bearing capacity, material performance, installation method, and compatibility with different cable sizes are the real decision points. Rubber-based designs are widely used because they handle repeated pressure while remaining flexible enough for fast setup and removal.

One common question from project managers is whether standard products are enough. In many cases, site layouts differ, cable diameters vary, and color marking is required for visual identification. This is why working with experienced Cable Protector Manufacturers matters. Manufacturers with in-house R&D and tooling capabilities can adapt molds, channel widths, or surface textures based on drawings or samples. This shortens communication cycles and avoids repeated adjustments during production.

From a sourcing perspective, buyers also care about consistency. Large-scale events or long-term infrastructure projects often need a stable supply rather than one-time purchases. Professional Cable Protector Manufacturers with mature production lines and bulk output capacity are better positioned to support repeat orders without changing product specifications. This consistency reduces inspection time and simplifies warehouse planning.

Material and load considerations

Rubber cable protectors are commonly selected for areas with rolling loads, such as forklifts or light vehicles. The internal channel structure distributes pressure while keeping cables separated. For indoor use, surface patterns may focus more on grip and visibility, while outdoor environments often require resistance to temperature changes and moisture.

Customization and OEM cooperation

Many buyers underestimate how early customization decisions affect installation efficiency. Channel count, cover opening style, and connection design influence how fast a Cable Protector can be deployed on site. OEM support from capable Cable Protector Manufacturers allows these details to be refined before mass production, avoiding on-site modifications later.